Revamping

The indispensable condition for increasing the efficiency and flexibility of an industrial production line is the use of efficient and modern equipment and machinery. The history of Automation Systems Technology is full of Revamping projects with which old and obsolete industrial automation equipment and systems have been made efficient and productive again.

Automation Systems Technology can support 360° the customer who needs to intervene on obsolete plants, with Revamping activities to increase production without necessarily having to replace the plant itself.

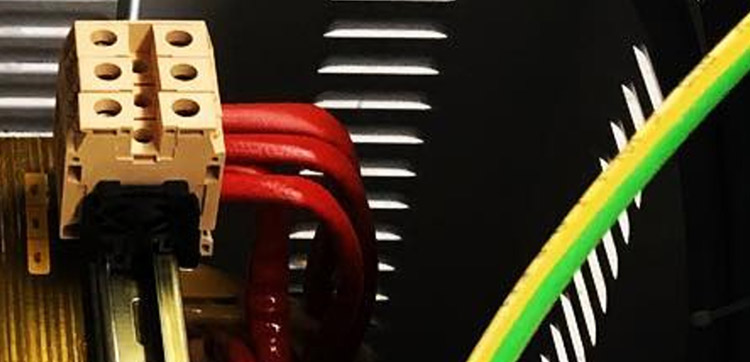

Automation Systems Technology carries out targeted interventions to replace and remake electrical panels, PLC control systems, obsolete drives and drives for axis movement and the part of the machine edge wiring, replacing connection cables and ducts, inserting functional junction boxes and all those elements that lead to an increase in productivity, energy saving and safety.

The average life span of an automatic system is around 20 years. The sudden change in the technology of the electrical/electronic part, involves, with the passage of time, more and more difficulties in keeping reliable a system based on a mechanical part still efficient, but with increasing problems in finding spare parts related to motors, drives, PLCs and electromechanical devices, which have become obsolete.

Automation Systems Technology provides a hardware replacement and software remake service, with the aim, in addition to updating the components, to improve the efficiency and performance of the plant, also adapting it to the likely changed business needs. Automation Systems Technology ensures the re-engineering of existing production systems and machinery, customizing applications and implementing new automation rules, to achieve greater quality control and increase production. Thanks to the experience gained in years of plant revamping and modernization, Automation Systems Technology is able to guarantee interventions with very short downtime, taking advantage of periods of company downtime.

Revamping: what is it and why is it beneficial to do so?

Revamping is an operation of restructuring and refurbishment of even complex industrial plants in order to extend their life cycle within the production process. In detail, a revamping operation replaces the technological heart of an industrial machinery, updating it with current and advanced solutions that allow the plant to gain efficiency and quality, while maintaining the original structure. Thanks to revamping, it is therefore possible to restore obsolete technological processes, replacing them with modern technologies that allow the plant to start a new productive “life”, thus obtaining an increase in productivity, energy saving and safety.

A revamping operation provides several advantages, including:

- Increased staff security

- Improved quality and production flexibility of the line

- Increased productivity and plant performance

- Reduction of production costs