Food sector

The know-how acquired by Automation Systems Technology over the years allows the company to present itself as a valid partner for all those companies and companies operating in the food industry, for the construction of electrical systems and equipment in one of those sectors where continuous research to improve the product and increase productivity pushes automation to the highest levels and requires performance at the top of the category.

Automation Systems Technology has developed over the years a knowledge able to adapt the systems to the continuous changes that take place in the production machines, which comply with the requirements of the main food regulations.

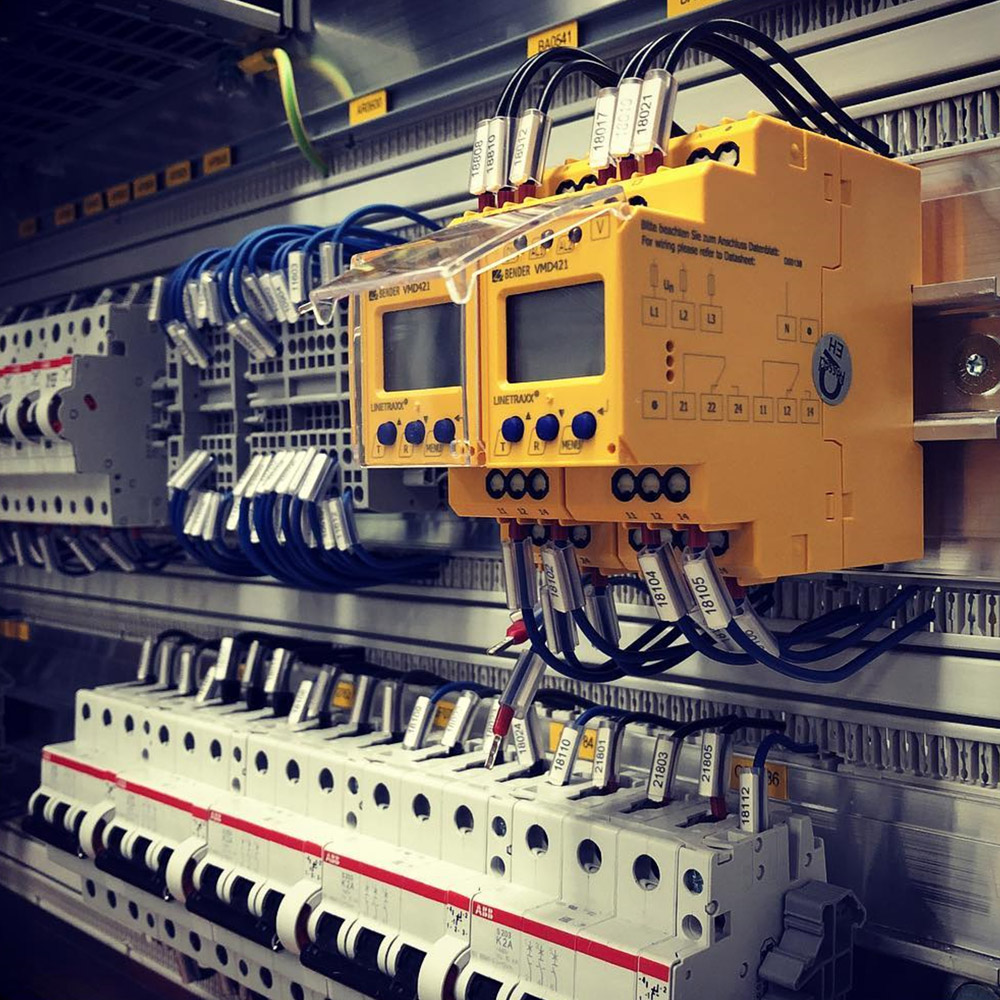

Switchboards in stainless steel Aisi 304 and 316, Switchboards to increase productivity in the sector, Switchboards for automation in packaging, for product packaging, kneading and mixing lines. Switchboards for packaging lines and packaging machinery such as packaging film lines, printing machines, flexo, laminators, cutters.

Among the most important projects developed in the sector, the company boasts the realization of:

- Process control and supervision systems for starch production plants

- Automation and supervision for storage plants

- Factory integration and back up systems

- Process control and supervision systems for concentration plants

- Batch and continuous production plants for semi-finished products from finished cereals

- Syrups demineralisation and decolourisation plants

- Egg reception and distribution process control and supervision systems

- Control and supervision systems for Cleaning In Processing wash management cycles

- Control and supervision systems at the end of the fresh products line and interfacing with Laser systems

- Integrated data collection systems for milk collection traceability management

- Control and process supervision systems for creams production plants

Some installations made

Project info

Categoriy

Food sector plant

Project description

Design and supply of an automation and control system for a line for stacking, pulmonary and automatic multipack packaging of crackers, biscuits and rusks, from the production line to the creation of the portions, to the automatic management of a packer according to the particular needs related to the conformation of the customer's production site.

Purpose of supply

- Supply of two electrical panels with special carpentry to design for the assembly on board of the machine for the automation of N.2 loader belts.

- Supply of an electrical panel containing the PLC for the control of the portioner and the wrapping machine

- PLC software engineering and development

- Engineering, architecture and development of SCADA control software

- Installation and wiring of field instrumentation and switchboards

- Issue of electrical technical design documentation, CE certification and operating manuals

- Commissioning and start-up activities

Project info

Category

Food sector plant

Project description

Design and supply of an automation and control system for a complete line for the production and packaging of whole peeled and diced tomatoes, from the reception of the raw material to the packaging of the canned product (can) and palletization of the final packaging in cartons or packs wrapped in shrink film.

Purpose of supply

- Design and construction of an electrical panel for the automation of the loading system consisting of a system for conveying and tilting the bins, a system of conveyor belts for feeding the washing tanks and a group of hoppers, screw conveyors, channels, etc.. for the collection and recovery of waste processing and peeling.

- Design and construction of an electrical panel for the control and monitoring of the pre-washing and product washing tanks

- PLC control panel in redundant configuration for the automation and control of the entire system composed mainly of:

- Optical sorting machine

- Vacuum filler group complete with seamer monobloc execution for cans

- Palletizer / Depalletizer for product packaged in neutral cans

- Rolling carton labelling machine with cartoning machine for cans and automatic packaging machine for shrink-wrapped packages

- PLC software engineering and development

- Engineering, architecture and supervision software development

- Installation and wiring of field instrumentation and switchboards

- Issue of electrical technical design documentation, CE certification and operating manuals

- Commissioning and start-up activities